Kater Pendulum Theoretical Considerations

Randall D. Peters

Department of Physics

Mercer University

Macon, Georgia 31207

1 Idealized Kater Pendulum

Consider a uniform

rectangular pendulum as illustrated in Figure 1. One axis of rotation is

an end, and we wish to find another axis for which the periods of oscillation

about the two parallel axes are the same. Note that the pendulum must be

turned upside down to oscillate about axis 2, the adjustable knife edge.

Figure 1: Illustration of a simple Kater pendulum.

For small amplitudes of free decay,

the equations of motion are given by Ii d2q/dt2 + MgLiq = 0;

and the moments of inertia are

by use of the parallel axis theorem.

If the pendulum length L is considerably greater than its width or

thickness, then the center of mass moment is given by

Ic = ML2/12.

Additionally, L1 = L/2, and L2 is to be determined.

From the solution

to the equation of motion, the periods are found to be

It is convenient to define the radius of gyration, k, whereby

Ic = Mk2. From equations 1 and 2, the condition T1 = T2

requires that

|

k2 = L1L2 for period matching |

| (3) |

Additionally, since k = L/121/2, we see that

L2 = k2/L1 = L/6.

Thus, for the matched condition,

|

T1 = T2 = T = 2p[(L1 + L2)/g]1/2 = 2p[2L/(3g)]1/2 |

| (4) |

We thus see that the pendulum, for the matched period condition, is

equivalent to a simple pendulum of length 2L/3.

1.1 Variation of Period with Axis Position

It is

instructive to consider the pendulum as outfitted with a hypothetical

single axis, rather

than the two required for operation, and look at the variation of period

with the position y of this

single axis relative to the center (of mass) of the pendulum, in the range

from 0 < y < L/2, as shown in Figure 2.

Figure 2: Period vs axis position for a pendulum of Figure 1 type.

The first thing one should note from Figure 2 is that there are two cardinal

axis positions-one at L/2 and the one which yields the same period

at L/6. The length of the pendulum for Figure 2 was chosen at

L = 37.25 cm to yield a 1 s period when g = 9.803 m/s2.

2 Non-Ideal Features

2.1 Effect of Period Difference

Ultimately, there will always be a measurable difference

between the periods, T1 and T2, but attempts

to match them is an exercise that is unnecesary, since the effect of

small difference can be factored

into one's estimate for the acceleration of gravity g .

Imagine that the position of pivot 2

could be changed by a small amount, D, from

its nominal L/6 from the center of the pendulum.

(In our initial consideration of the influence of departures from ideal

geometry, the offset distance of pivot 1 from the end of

the pendulum will be ignored-a complication which will be addressed later.)

The dependence of T2 on D is determined by two factors: (i) the

moment arm of the gravitational force and (ii) the change in the moment of

inertia about the pivot (readily calculated using the parallel axis theorem).

The period is found to obey

which is seen to equal T1 when D = 0.

Assume that one makes an accurate measurement of the separation distance

between the two pivots

By expanding the square root term in (5) with the binomial theorem

and retaining terms only to

first order in D, one obtains

which combines with (6) to yield

The usefulness of (8) derives from the manner in which lm changes with

the ratio T2/T1.

If T2/T1 > 1 then lm < 2/3L. On the other hand if

T2/T1 < 1 then lm > 2/3L. Moreover,

Equation (8) provides automatic compensation over a surprisingly large

range of deviations in DT = T2-T1, for reasons that can be

appreciated qualitatively

by studying Figure 2.

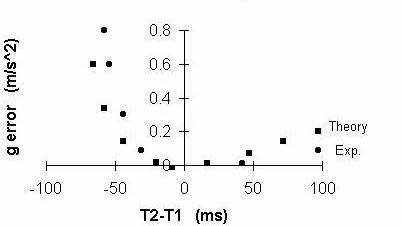

A quantitative indicator of the compensation of Eq. 8 is

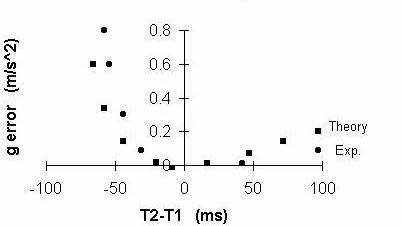

provided in Figure 3.

Figure 3: Errors of Eq. 8

To generate the experimental results, a very crude

pendulum was cut out of aluminum with a hacksaw to the approximate size of

the TEL-Atomic instrument. An end 1/4 in hole was drilled for axis-1, and

7 axis-2 holes were drilled at various positions around the 2L/3 point. The

total range of distances between the axes was 5.7 cm. In this range, the

period difference

T2-T1 varied from -58 ms at 28.2 cm separation to 97 ms at 22.5 cm

separation of the axes.

Eq. 8 is not capable of fully describing this

system because it corresponds to a 2-hole pendulum rather than the 7-hole

pendulum tested. Nevertheless the equation fits the data reasonably well

as shown in Figure 3. Interestingly, over the full 5.7 cm range, the largest

error in the g estimate does not exceed 8%. Moreover, for a certain 3 cm

range (favoring smaller as opposed to larger than nominal separations), the

error does not exceed 1%. For tolerances on hole placement held to

approximately 1 mm, Eq. 8 results in errors not to exceed 1 part per 10,000.

It is worth repeating-errors in the placement

of the axis-2 hole are less significant if its placement is shy of

(as opposed to greater than) the

L/6 nominal distance from the center.

One must recognize a shortcoming to the utility of Eq. 8 as compared to the

more elaborate method of using a small mass slider as described in

the operational part of this manual. The relative uncertainty in the

estimate of g, when using eq. 8 is given by

|

dg/g = [(dlm/lm)2 + (2dT2/T2)2 + (3dT1/T1)2)]1/2 |

| (9) |

Weighting by the factor of 3 in the T1 errors (due to the cubic term)

requires more careful period measurement as compared to

the slider method.

In spite of the extra contribution to the uncertainty in g, Eq. 8 is

still quite useful. For example, it was used with the data obtained

from the TEL-Atomic pendulum employing a 2.6 g slider. The errors of

Fig. 4 derive from the calculation of g by means of quadratic

fits to the T1 and T2 data. They are seen to be less than one

part per thousand for every position of the slider between 0 and 30 cm.

Figure 4: Errors in g estimate using Eq. 8 on TEL-Atomic pend. with slider

3 Practical pendulum

The idealized rectangular pendulum treated above is not practical, since

axis engineering has been ignored. Some things that were

tried unsuccessfully involved (i) bearings mounted in the pendulum for

sharpened pins to ride against, and (ii) small cylinders inserted

through the

pendulum. The only practical means found for providing axes

is the scheme next described, involving a pair of holes drilled through

the pendulum.

3.1 Configuration with a pair of holes for a knife edge

Let each hole be of radius r, their centers being located

at y1 (positive) above the center of the pendulum, and

y2 (negative) below the center. Since y2 is in magnitude less than

y1, there is a small negative shift of the center of mass of the pendulum

with respect to the center of the rectangle (-0.8 mm for the TEL-Atomic design).

The position of

the center of mass is given by

|

yc = -p r2(y1 + y2)/(Lw - 2pr2) |

| (10) |

where L is the overall length of the pendulum and w is its

width.

If there were no holes in the pendulum, its mass normalized

moment of inertia, with respect to the center of mass

(c.m. = geometric center), would be

|

Ic, ideal = (L2 + w2 )/12 |

| (11) |

where t is the thickness.

Although the term involving t = 0.32 cm is presently ignorable, the one

involving w = 1.3 cm

is not (as compared to L = 37.4 cm). To match the periods about the two axes to a few parts in 10,000

requires the computer. The easiest way to accommodate the holes

is to treat them as negative masses. By using this technique and

the parallel axis theorem, one obtains

the following expression for the nonideal mass normalized c.m. moment:

|

Ic = [(L2+w2)Lw/12+Lwyc2-pr2[(y1-yc)2+(y2-yc)2]-pr4]/(Lw - 2pr2) |

| (12) |

To estimate the period for each of the axes, it is necessary to

specify the distance of each axis from the center of mass:

d1 = y1 + r - yc

d2 = y2 - r - yc |

| (13) |

in which care must be taken with regard to algebraic signs.

Using then the moments of inertia

I1 = Ic + d12

I2 = Ic + d22 |

| (14) |

the periods are found to be

T1 = 2p[I1/(gd1)]1/2

T2 = 2p[I2/(g(-d2))]1/2 |

| (15) |

3.2 Design of the TEL-Atomic pendulum

The holes were selected to be 0.25 in diameter, and w = 1.3 cm so

that the amount of side material at the axis-2 position would be

adequate for structural integrity. Similar considerations figured

into the placement of the axis-1 hole; i.e., the distance from the center

of the pendulum was chosen at 18.18 cm to give a 2 mm piece of

metal where the knife edge rides.

The length L = 37.4 cm and the axis-2 hole position of y2 = -5.995 cm

were obtained by programming the computer

with the equations given above, and allowing L and y2 to vary.

The objective was to select for these values a matched

condition corresponding to a period of 1 s.

For a small set of L values (expected from idealized pendulum

considerations to be in the neighborhood of 37 1/2 cm), y2 was

allowed to vary quasi-smoothly through a range which permits T1 = T2.

In the calculations, g was set to 9.797, and

the matched period condition is one which yields for the estimated

acceleration of gravity

g = 4p2 (d1 - d2)/T2, T = T1 = T2

with d1 = 18.58 cm, d2 = -6.232 cm |

| (16) |

Note that the nominal simple pendulum equivalent length is

d1 - d2 = lm (Eq.8) = 24.81 cm.

For the indicated parameters, the nominal period values were

T1 = 0.9998 s and T2 = 0.9999 s. Attempts to get

closer to unity

were found to be futile for reasons that probably derive from

the brass of the pendulum being less than perfectly homogeneous in

terms of mass density.

For example, one pendulum to the next typically shows deviations from the

nominal periods on the order of 5 parts per 10,000.

File translated from TEX by TTH, version 1.95.

On 19 Nov 1999, 11:23.